What is a dispersion adhesive? Uses

- Types of dispersion adhesives

- Lux water-based dispersion adhesives

- Where are Lux water-based dispersion adhesives used?

- Lux PVAc adhesive is used in:

- Why Lux-X dispersion adhesives?

- How to buy the Lux dispersion adhesive.

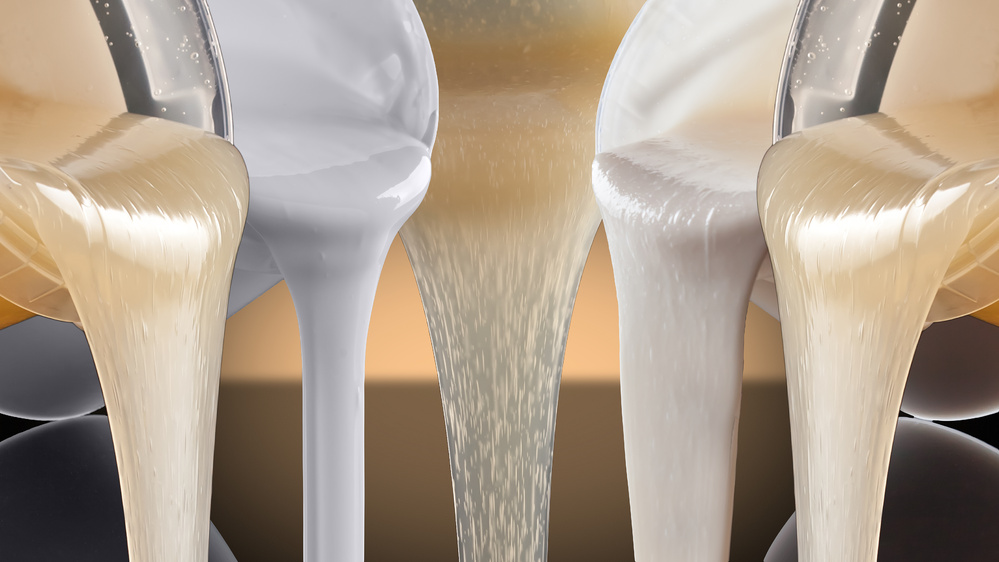

A dispersion adhesive is a mixture of organic or synthetic polymers dispersed in a liquid. Depending on the composition, a dispersion adhesive can bond various materials - paper, ceramics, metal, wood, glass, fabric and other surfaces.

For high-quality bonding, it is best to select an adhesive for certain types of materials. The strength and quality of the adhesive bond depend on the right adhesive for the materials to be bonded, equipment and technology for applying the adhesive.

Types of dispersion adhesives

1 Water-based dispersion adhesives. The adhesive is based on water, which acts as a solvent. Common types of water-based dispersion adhesives include:

- Plant polymer-based adhesives: starches or dextrins. The colour of the adhesive ranges from orange to brown. The adhesive is characterised by high viscosity, tackiness and low cost. It is used in packaging manufacturing and labelling.

- Adhesives based on animal-derived polymers, e.g., casein adhesives. Their colour ranges from orange to brown. They are used for labelling beer bottles, alcoholic beverages and soft drinks.

- Adhesives based on synthetic polymers such as ethylene vinyl acetate (EVA) and polyvinyl acetate (PVAc) emulsions. PVAc is the most common type of dispersion adhesive. The colour ranges from milky to white. They bond wood, paper and other surfaces.

- Natural or synthetic rubber-based adhesives - latex adhesives. They are a mixture of latex, filler and water-based additives. They are white in colour. They are used in manufacturing furniture and the printing, construction and textile industries.

2 Solvent-based adhesives. They are a mixture of solvent-based polymers. Solvent-based adhesives can be single-component or multi-component - two or more.

The single-component adhesive hardens with the help of moisture from the air, which reacts with isocyanate groups.

Two-component adhesives usually consist of a polymer and an isocyanate hardener.The adhesive mixtures are prepared by mixing two or more components. Hardening occurs as a result of a reaction when the ingredients are mixed in certain proportions.

Solvent-based adhesives provide high bonding strength and good performance. However, they are becoming less popular because they contain volatile organic compounds, which are harmful to humans and the environment.

In many developed countries, water-dispersion adhesives are the most popular. They have the required strength characteristics for bonding various materials and have an environmentally friendly formula.

Lux water-based dispersion adhesives

Lux-X manufactures water-based dispersion adhesives under the Lux brand for many areas of application.

Where are Lux water-based dispersion adhesives used?

- Labels and excise stamps.

- Packaging and printing.

- Woodworking and furniture manufacturing.

- Textile industry.

- Construction and repairs.

Lux water-based dispersion adhesives for labels are made from casein, starch, polymers and resins.

Casein adhesives are characterised by high resistance to icy water and condensate, which is critical when bonding labels on beer and champagne bottles. The adhesive can be applied both manually and using various types of labelling equipment, including high-speed lines operating at up to 60000 bottles per hour. Also, this type of adhesive is free of harmful ingredients, which is why it is used in manufacturing environmentally friendly products.

Water-soluble adhesives based on modified starches are used on labels on dry glass containers at temperatures of up to 40ºС.

Resin and polymer-based dispersion adhesives can be used on labels and excise stamps. They can be applied manually or using various types of labelling equipment at a rate of up to 30000 bottles per hour.

Lux adhesives for packaging and printing are made from synthetic polymers (PVAc, EVA, PVC, acrylates and other polymer bases) and are used in:

- production of cardboard, wound cardboard containers and containers with a composite polymer coating, lamination of finishing and construction materials;

- printed and printing products: for gluing a block into a cover, laminating and forming a cover.

- cold lamination of cardboard with paper and polymer films, including those coated with UV varnish.

Lux PVAc adhesive is a water-based dispersion adhesive based on polyvinyl acetate, which is widely used for industrial purposes, in construction and at home. Besides various brands of PVAc-based adhesives, Lux-X manufactures a PVAc dispersion with high adhesive strength. The unplasticised PVAc dispersion has frost-resistant properties and can withstand several freeze-thaw cycles.

Lux PVAc adhesive is used in:

- woodworking and furniture manufacturing: all types of installation bonding, tongue-and-groove joints, bonding hard and soft wood, plywood, etc.;

- construction work, including bonding linoleum and facing tiles;

- textile industry: bonding leather, foam rubber, fabric-based products;

- it is recommended as an additive to lime and cement mortars, putties, water-based paints, etc.

The Lux wallpaper adhesive is a separate group of dispersion adhesives.

The Lux wallpaper adhesive is an all-purpose adhesive compound for wallpaper, having high adhesive performance. High bonding strength allows quick and lasting adhesion of the wall or ceiling cover throughout the service life. The adhesive is made from environmentally friendly ingredients, which makes it safe for humans and pets.

The all-purpose wallpaper adhesive is suitable for all types of wall coverings: fibreglass wallpaper, glass cloth, vinyl, non-woven, paper and other types of wallpaper.

Why Lux-X dispersion adhesives?

- We offer a wide range of high-quality water-based adhesives.

- We tailor the adhesive to the customer’s needs, taking into account the characteristics of the enterprise.

- We help to set up equipment for applying the adhesive.

- Customers can get discounts depending on the volume. And for orders above 30 kg, delivery is free across Ukraine.

How to buy the Lux dispersion adhesive.

You can order the adhesive or get advice by calling +38 (057) 766-06-36 or at lux-x.com.