Concrete impregnation agents: their definition, types and purpose

- What is concrete impregnation and how is it used?

- The purpose of using concrete impregnation agents

- Types of concrete impregnation agents

- The advantages of concrete impregnation based on hydrated silicate and modified acrylics.

- Methods of applying concrete impregnation agents

- What is the impregnation consumption rate for concrete based on hydrated silicate and modified acrylics?

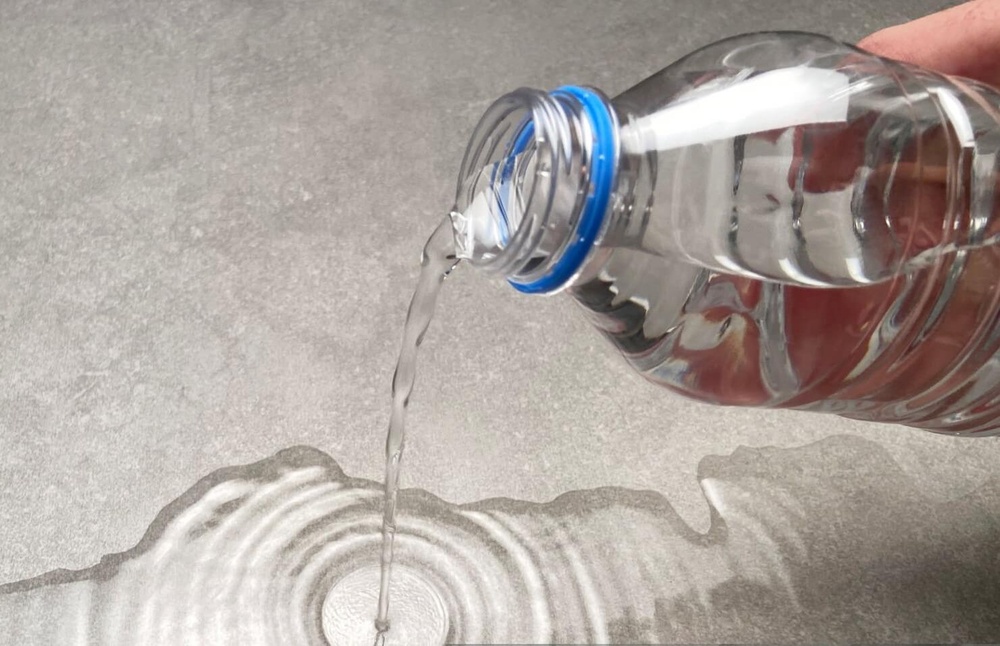

Concrete is one of the most durable construction materials, which is why it is used to construct military and civilian structures, including shelters, industrial, commercial, administrative buildings, infrastructure, warehouses and residential buildings. It is highly durable and reliable. Concrete structures can easily last for many years without requiring major repairs. However, even such a durable material has one small but significant drawback: its pores, as concrete becomes saturated with moisture, salts and various chemical compounds due to winter surface treatment. This leads to its destruction and puts the facility in an emergency condition. Using a special concrete impregnation agent will help prevent this, and Lux-X offers its own product, Hardener-C. This article will take a detailed look at the features of impregnation agents, their advantages, functions, and specific application methods.

What is concrete impregnation and how is it used?

This is a special adhesive composition designed to create a barrier between concrete and its surroundings. It is also known as a hydrophobic agent, primer or fixative due to its water-repellent properties. The composition penetrates all pores and cracks in the material's surface, filling the space completely and providing proper protection for the concrete structure against destruction caused by external factors. In other words, it is a special agent designed to enhance the material's properties and technical specifications, thereby extending the facility's lifespan.

The purpose of using concrete impregnation agents

Concrete impregnation agents are used for various purposes in different fields of economic activity.

- Increasing the strength of the concrete structure. The hydrophobic agent penetrates deep into the material and fills even the smallest of pores. It does not dissolve or wash out, and remains effective for a long time, protecting the concrete throughout the facility's long service life. After treatment, an invisible protective coating forms on the concrete surface. This coating prevents damage caused by moisture, salts, chemical reactions and ultraviolet radiation.

- Extending the life and reliability of concrete structures. Since the filling penetrates all pores and the smallest of cracks, it provides reliable insulation for concrete against moisture and exposure to aggressive chemicals. Moreover, concrete structures become more resistant to low temperatures and their fluctuations. Cracks do not appear in them due to the freezing and thawing of water, meaning the structures last longer.

- Budget savings. Any structure must be serviced periodically and undergo minor and major repairs to ensure it is maintained in good technical condition and to prevent accidents that could endanger people's health and lives. All of this incurs additional costs, which can be significantly reduced by using impregnation agents on concrete floors and other surfaces. Since it increases strength and reduces the risk of damage, it will also increase the reliability of the structure. This will enable you to reduce the frequency of scheduled repairs and save money on maintenance costs.

Types of concrete impregnation agents

There are two types of hydrophobic agents:

- polymer-based or organic, they penetrate the pores of concrete to provide a basic level of protection;

- based on silicates and modified acrylics, they penetrate all pores and react with the material at a molecular level to provide a long-lasting waterproof effect.

Due to their high efficiency and functionality, compositions from the second category are more popular impregnation agents for concrete, and these are the agents produced by Lux-X. The product enhances the water resistance and strength rating of building materials, improving their overall properties and making concrete structures more reliable and durable.

The advantages of concrete impregnation based on hydrated silicate and modified acrylics.

The Hardener-C hydrophobic agent has the following advantageous properties:

- it is all-purpose, meaning it is suitable for treating both indoor and outdoor structures;

- highly reliable and effective, due to its concentrated composition;

- it increases strength and wear resistance;

- has increased water resistance, providing protection against concrete cracking and the destruction of the entire structure;

- it prevents dust from settling on the concrete surface;

- protects against various chemicals whose effect also leads to a decrease in structural performance;

- complies with the fire safety rules because the hydrophobic agent is non-flammable;

- can be used with dry hardeners.

Important note: the impregnation agent for concrete floors and similar surfaces can irritate the skin and mucous membranes. Therefore, when working with it, you should take care to use the necessary personal protective equipment. If the product comes into contact with your eyes or skin, rinse thoroughly with water and seek medical attention.

Methods of applying concrete impregnation agents

The technical description of the hydrophobic agent contains a detailed application algorithm. In this article, we will briefly summarise the main points:

- The impregnation agent acts as a primer, meaning that the surface cannot be pre-primed or painted; otherwise, the components of the composition will not be able to penetrate the concrete's pores. The only permitted action is to apply an impregnation agent to a concrete base that has already been treated with a similar agent.

- The concrete surface must be properly prepared and the environmental conditions must be suitable. Thorough cleaning is required to remove dust, dirt and cement laitance. The surface must be smooth and dry. If necessary, use a grinder and a vacuum cleaner prior to treatment. In terms of environmental conditions, work can only be carried out at temperatures above zero – between 5°C and 30°C. After treatment, the surface should not get wet. If it is an outdoor structure, be sure to check the weather forecast.

- The concrete floor and other surfaces should be evenly impregnated – a microfibre mop can be used for this purpose. There should be no puddles or dry areas. If there is a large amount of primer, its remnants can be removed with a soft scraper after about an hour.

- The primer must be applied in several layers, with each layer being pre-dried before the next is applied.

Keep in mind that the product is corrosive. Remove or securely protect any metal or glass products before treatment.

What is the impregnation consumption rate for concrete based on hydrated silicate and modified acrylics?

The exact quantities required depend on the roughness and quality of the concrete and the size of the cells. On average, however, 1 kg of primer is enough to cover 4–6 m² of surface area per layer.

Our company produces and sells concrete impregnation agents in polymer containers, with weights ranging from 10 to 1000 kg. We guarantee the high quality of our products by using raw materials from trusted suppliers and by strictly adhering to production technology. For more information and to place your order for impregnation agents, please call or email us.