Adhesive for corrugated cardboard and corrugated packaging

- Corrugated cardboard packaging

- Protecting corrugated packaging from moisture

- Adhesive for corrugated packaging

- Recommendations for using Lux TM water-based adhesives

- Recommendations for working with ВАМ hot melt adhesives for gluing packaging

- Where to buy an adhesive for corrugated packaging

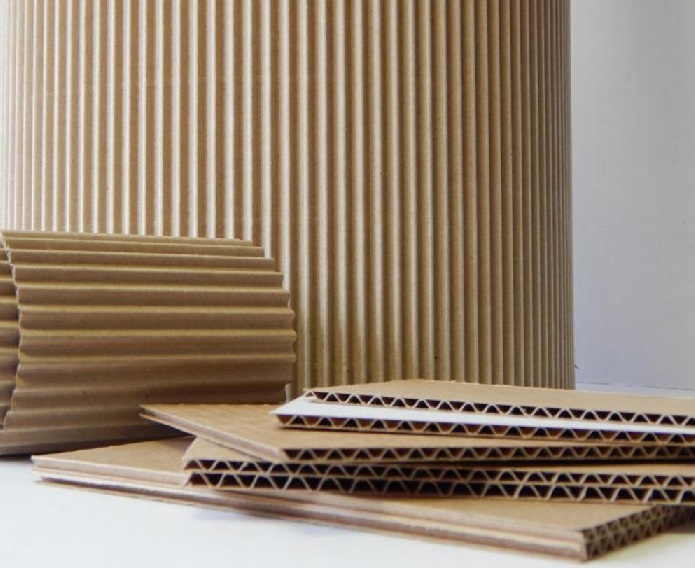

Corrugated cardboard is the most common material used for making packaging. The advantages of corrugated cardboard are as follows: low price, durability and ecological compatibility. Corrugated cardboard is made of several layers of paper stock. Triplex cardboard is the material used in most cases to make packaging. The cardboard layers are joined by corrugated paper.

When making corrugated cardboard, its layers are bonded usually by using dextrin-based adhesives. Previously, corrugated cardboard layers were bonded with silicate glue. But since the glue dries long and its consumption is big, and it adversely impacts the equipment condition, manufacturers gradually declined using it.

When making corrugated cardboard packaging, the adhesive is chosen depending on the equipment that is being used for applying the adhesive and for what purpose: backing, fold sealing, gluing packaging flaps, etc.

Corrugated cardboard packaging

The market offers different kinds of packaging made of corrugated cardboard: cases, boxes, and pallets. Corrugated cardboard lends itself well to the following finishing processes: backing, laminating, colouring and printing. Backing gives the coating an appealing appearance and improves the product consumer value.

Cardboard boxes are used for packing products for children, foodstuff, non-food items and other goods. Corrugated packaging is durable and protects products well from physical damage. Apart from the protection function, the packaging advertises the product and informs consumers of its characteristics.

Protecting corrugated packaging from moisture

In spite of the advantages of corrugated cardboard, its essential drawback is moisture pickup. To protect corrugated cardboard from moisture and keep the product intact under the effect of adverse ambient conditions, manufacturers use special waterproofing compounds that are added to the paper pulp or applied onto the cardboard surface to create a firm waterproof film.

Lux-Х LLC has contributed to the development of the packaging industry by developing a waterproof coating for making corrugated cardboard. Tests under elevated moisture conditions have shown that the moisture fastness of the corrugated cardboard surface coated with the Lux waterproofing compound is far more effective than that of the corrugated cardboard, to which the waterproofing compound is added when producing the paper pulp.

Flexographic machines are used to apply the Lux waterproofing coating as an even layer on the corrugated cardboard surface before printing and cutting. The product is safe and easy to use, permits contact with food products, and allows printing on the dry cardboard surface.

Corrugated packaging, treated with the Lux waterproofing coating, remains durable under elevated moisture conditions and keeps its integrity during transportation. Apart from the waterproofing coating, an important material for making corrugated packaging is the adhesive.

Adhesive for corrugated packaging

Several operations are needed to make corrugated packaging: gluing the sidewalls of the article, sealing up the covers and the bottoms of the boxes, joining the cardboard elements with polyethylene, PVC and other materials. A suitable adhesive is needed to ensure a standard production process level and create durable corrugated packaging.

A water-based adhesive or a hot melt adhesive is used for making corrugated packaging.

Industrial-grade water-based adhesives for corrugated packaging have the following properties:

- Fast adhesion to the surface being glued.

- Nontoxic and environmentally safe.

- Create strong and reliable bonding.

Water-based adhesives are used for making cardboard and spirally wound cardboard containers, corner protectors, cartridges, and sleeves. They are also used for backing, and for gluing paper bags and other paper and cardboard articles.

Lux-Х LLC offers a wide range of water-based adhesives for corrugated packaging:

- Lux-Р and Lux ЕСО line of adhesives;

- PVAc adhesive;

- PVAc dispersion.

LUX ТМ adhesives are ecologically clean products made exclusively of safe components. They are characterised by enhanced adhesion and are recommended for gluing packaging for foodstuffs and products for children.

Recommendations for using Lux TM water-based adhesives

- Lux adhesive is applied onto corrugated packaging parts with roller and disc machines.

- The adhesive consumption rate depends on the type of equipment and operating temperature.

- The adhesive guaranteed shelf life is 4 months from the date of production.

- Adhesive application temperature is from +15 оС to +35 оС.

- When being used with other adhesives, the chosen adhesive must be checked for compatibility.

To glue corrugated packaging, Lux-Х LLC offers hot melt adhesives produced by the English company BeardowAdams. ВАМ adhesives are used for the following tasks:

- Gluing flaps of cardboard boxes.

- Assembling pallets and wrapping packages.

- Fastening covers on Tetra Pack carton packages.

- Gluing packages for frozen food.

- Gluing straws to carton packages for beverages.

BAM TM hot melt adhesives for packaging have the following properties:

- Transparent or light adhesive hue that forms an unnoticeable glue joint.

- No toxic odour and fumes.

- High heat resistance: the packaging maintains its integrity when stored under conditions of high and low temperatures.

- Does not clog gluing machines and is easy to clean.

- High adhesion and stickiness ensure fast and durable bonding, making the adhesive perfectly suitable for use with high-speed packaging lines with small joining times.

Recommendations for working with ВАМ hot melt adhesives for gluing packaging

- Apply the hot melt adhesive by using nozzles, a sprayer, drum or roller.

- Maintain the application temperatures of 150 °C to 170 °C depending on the material being glued.

- To prevent adhesive decomposition, adjust the thermostats and maintain the working temperature within 200 °C.

- When applying the hot melt adhesive with nozzles make sure that the adhesive viscosity is high and the equipment is adjusted properly; otherwise, the adhesive will splash over the entire coating and clog the machine.

- Keep the hot melt adhesive in closed containers in a dry place at an ambient temperature 5 °C to 30 °C.

Where to buy an adhesive for corrugated packaging

We recommend a responsible approach to choosing an adhesive for making corrugated packaging. This will have an impact not only on the packaging quality, but also on the producer’s standing. An adhesive for corrugated packaging can be purchased wholesale

directly from the producer – Lux-X LLC. By contacting us, the company’s technical experts and managers will help you choose the adhesive you need and consult you on the product price.

Delivery is free-of-charge when ordering an adhesive in industrial-scale volumes.

You can get professional consultation and order an adhesive by telephone +38 (057) 766 06 36 or by using the contact form on the Lux-X website.